What is threadolet (threaded outlet) ?

A threadolet is the same basic design as a “weldolet.” However the main difference is the fitting has a female threaded connection to mate to the branch connection. This makes a 90° branch and comes in full size or reducing for a straight piece of pipe. It typically is in the size range of 1/2″ to 2″ and is welded over a hole either drilled or burned in the pipe.

You use a “weldolet” when you want to weld a pipe or fitting directly to the branch fitting and a “threadolet” when you want to screw the connecting pipe or fitting (e.g. valve) to the branch connection.

I believe there is a ANSI standard for the dimensions and pressure rating of these type of fitting.

Depending of the relative size of the olet and the main pipe run the affect can vary from no affect to causing the header to bow or warp due to the heating and cooling of the weld. A good run of thumb is to never use an olet that is larger that 1/2 the size of the main pipe run. Size in this case being the nominal size.

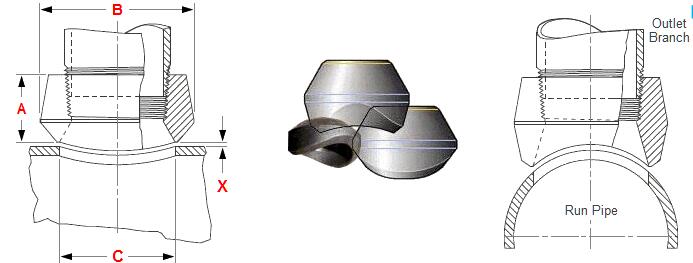

Dimensions Reducing Thredolet – MSS SP97

CLASS 3000

| NPS | A | B | C |

| 1/2 | 1 25.40 | 1.13/32 35.71 | 15/16 23.81 |

| 3/4 | 1.1/16 26.98 | 1.23/32 43.65 | 1.5/32 29.36 |

| 1 | 1.5/16 33.33 | 2 50.80 | 1.7/16 36.51 |

| 1¼ | 1.5/16 33.33 | 2.9/16 65.08 | 1.3/4 44.45 |

| 1½ | 1.3/8 34.92 | 2.27/32 72.23 | 2 50.80 |

| 2 | 1½ 38.10 | 3.15/32 88.10 | 2.9/16 65.08 |

| 2½ | 1.13/16 46.03 | 4.1/16 103.18 | 3 76.20 |

| 3 | 2 50.80 | 4.13/16 122.23 | 3.11/16 93.66 |

| 3½ | 2.1/8 53.975 | 5.7/32 132.55 | 4 101.6 |

| 4 | 2¼ 57.15 | 5.31/32 151.60 | 4.3/4 120.65 |

| 5 | 2.5/8 66.67 | 7.5/16 185.73 | 5.9/16 141.28 |

| 6 | 2.3/4 69.85 | 8.5/8 219.07 | 6.11/16 169.86 |

| NPS | A | B | C |

CLASS 6000

| NPS | A | B | C |

| 1/2 | 1¼ 31.75 | 1.23/32 43.65 | 3/4 19.05 |

| 3/4 | 1.7/16 36.51 | 1.61/64 49.60 | 1 25.40 |

| 1 | 1.9/16 39.68 | 2.7/16 61.91 | 1.5/16 33.33 |

| 1¼ | 1.5/8 41.27 | 2.23/32 69.05 | 1½ 38.10 |

| 1½ | 1.11/16 42.86 | 3¼ 82.55 | 1.15/16 49.21 |

| 2 | 2.1/16 52.38 | 4.1/32 102.39 | 2.3/4 69.85 |

| NPS | A | B | C |

General notes:

- Dimensions: Top Row in Inches / Bottom Row in millimeters.

- Root Gap – X – “Space” for welding the O’let is raised off the run pipe to establish proper weld gap by placing spacers, e.g. welding rods, under the fitting. This provides a uniform welding gap between the curvature of the run and base of fitting.

- Threaded Ends are in accordance with ASME B1.20.1. Design per MSS SP-97.

- Source comes from Bonney Forge (except the sizes in millimeters).

- Thredolet is a registered name. Another often used name is Threaded Outlet.

0 comments:

Post a Comment