Sweepolet is a contoured, integrally reinforced, butt-weld branch connection with a low stress intensification factor for low stresses and long fatigue life. The attachment weld is easily examined by radiography, ultrasound and other standard non-destructive techniques. Manufactured to meet your specific reinforcement requirements.

Standard:

ANSI, DIN, JIS

Material:

Carbon Steel

ASTM A 234 WPB

Stainless Steel

ASTM A403 WP304/304L, WP316/316L, WP321, WP347

Alloy Steel

ASTM A234 WP1, WP5, WP9, WP11, WP12, WP22, WP91

Schedule:

Carbon Steel & Alloy Steel

STD, XS, XXS, SCH10-SCH160

Stainless Steel

SCH5S, 10S, 40S, 80S

Size:

1/2”-48”

Type:

Sweepolet Saddle, Steel Saddle, Carbon Steel Saddle, Stainless Steel Saddle, Alloy Steel Saddle

Advantage Comparing With Tee:

1.Sweepolet Saddle can overcome the defeats in the process of making tee without weak point.

2. Sealed better and easy to be installed, it won’t affect main pipeline.

3. Sweepolet Saddle use less material than tee, so it has a more competitive price.

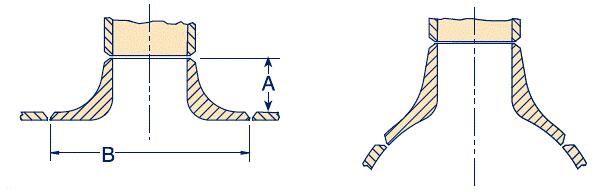

Sweepolet

| Run Size | Outlet Size Inches | Dimensions | |

| *A | B | ||

| 6 to 36 | 1 1/4 | 1 1/4 | 4 |

| 6 to 36 | 1 1/2 | 1 3/4 | 5 1/2 |

| 6 to 36 | 2 | 1 1/2 | 5 1/2 |

| 6 to 36 | 3 | 1 21/32 | 7 |

| 6 to 36 | 4 | 2 1/32 | 8 3/4 |

| 10 to 36 | 6 | 2 11/16 | 13 |

| 12 to 36 | 8 | 3 | 15 |

| 16 to 36 | 10 | 3 1/8 | 18 1/2 |

| 16 to 36 | 12 | 3 5/16 | 20 1/2 |

| 20 to 36 | 14 | 3 5/8 | 24 |

| 24 to 36 | 16 | 3 3/4 | 28 |

| 24 to 36 | 18 | 4 5/8 | 31 |

| 24 to 36 | 20 | 5 1/8 | 33 |

| 30 to 36 | 24 | 5 5/8 | 38 |

Weldolet Vs Sweepolet

Weldolets (aka WOL) are cheaper in terms of purchasing cost than sweepolets (aka SOL).

WOLs may, in some situations (large dia, thin wall) warp the pipe, i.e. unstraight and oval, due to excessive heat input arising form the relative thick required weld metal layer.

Since for WOLs the weld metal thickness is always greater than for SOLs (where one only welds the base metal wall thickness), welding may require some extra time to allow cooling off on the heat input to prevent banana-warping the pipe.

SOLs are less standard, I think most of the time custom made. Without having specific experience with SOLs, preparing and beveling the pipe for it may be more difficult/time-costuming compared to WOLs. For WOLs, you can weld them on, and then bore through the hole. This gives a smooth weld profile on the inside. This may give the best option for a flushing branch, as there is not weld metal ‘sticking into the run’ (provided the pipe doesnt become oval, as this will cause the pig trap to become stuck perhaps).

Since the saddle form is quite specific (but then again, the SOL may be laid down on the pipe, and the contour can be drawn), and a lot bigger than WOLs, more material has to be removed.

If you use a SOL and the run pipe is large enough in dia, you may counter grind the root weld to become flush.

WOLs can be RT-ed, SOLs can.

WOLs are likely to give more peak stress than SOLs, since the latter has a much more continuous profile into the branch.

0 comments:

Post a Comment