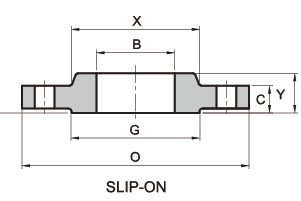

The Slip On flange has a low hub because the pipe slips into the flange prior to welding. It is welded both inside and out to provide sufficient strength and prevent leakage. Slip On flanges are all bored slightly larger than the O.D. of the matching pipe, They are preferred over welding neck flanges by many users due to their lower initial cost, but final installation cost is probably not much less than that of the welding neck flange because of the additional welding involved.

Slip On flanges or SO flanges are commonly lower in price than weld-neck flanges, and to this effect are a popular choice for our customers. However, customers should bear in mind that this initial cost saving may be diminished by the additional cost of the two fillet welds required for proper installation. Moreover, weld-neck flanges have a higher life expentancy than Slip On flanges under duress.

The Slip On flange is positioned so the inserted end of the pipe or fitting is set short of the flange face by the thickness of the pipe wall plus 1/8 of an inch, which thus allows for a fillet weld inside the SO flange equal without doing any damage to the flange face. The back or outside of the Slip On flange or SO flange is also welded with a fillet weld.

Slip On Flanges are probably the most common type of flanges in the industry and are ideal for lower pressure applications. You do not have to specify the pipe schedule when using Slip On flanges due to the fact that its inside diameter is determined by the outside diameter of the pipe. This outside diameter of the pipe does not change for the different schedules. This often makes these easier to stock for vendors. Fabricators also like the fact that these flanges are slightly easier to align than weld neck flanges. They also are slightly easier to cut pipe to the proper length for. They can be used for high temperature and pressure applications but are not generally recommended as compared to other types of flanges.

Slip On flanges or SO flanges are preferred by some contractors, over the Weld-neck, because of the lower initial cost. However, this may be offset by the added cost of the two fillet welds required for proper installation. The strength of the Slip On flange is ample for it’s rating, but its life under fatigue conditions is considered to be only one-third that of the weld-neck flange.

The Slip On flange may be attached to the end of a piece of pipe or to one or more ends of a pipe fitting. The Slip On flange is positioned so the inserted end of the pipe or fitting is set back or short of the flange face by the thickness of the pipe wall plus 1/8 of an inch. This allows for a fillet weld inside the SO flange equal to the thickness of the pipe wall without doing any damage to the flange face. The back or outside of the flange is also welded with a fillet weld.

A variation of the Slip On flange also exists. This is the Slip On Reducing Flange. This is simply a larger (say a 14″) Slip On flange blank that, instead of the Center (pipe) hole being cut out (or drilled out) for 14″ pipe it is cut out for a 6″ (or some other size) pipe. The SO Reducing flange is basically used for reducing the line size where space limitations will not allow the length of a weld neck flange and reducer combination. The use of the Slip On Reducing Flange should only be used where the flow direction is from the smaller size into the larger size.

A slip on flange is bored so that it does indeed slip onto the pipe so that the end of the pipe is just inside the flange a fraction of an inch from the flange face. The pipe end has been cut square. The flange bolt holes are aligned and the flange face squared to the pipe. Then a fillet weld is run around that end of the pipe to fuse it to the inside of the bore of the flange. Another fillet weld is run around the back end of the flange hub fusing it to the outside of the pipe. This is the most common welding flange. Before the final full fillet welds are made, temporary tack welds are made until alignment is assured. These tacks are easy to cut out so a correction can be made.

There are socket-type Slip On flanges where only the outside weld is made. The squared pipe end butts against a lip inside the flange bore.

| Product name : slip on flanges | |

A Slip On Flange is slightly larger than the outer diameter of the pipe it is to be used with. The pipe is slipped into the Flange prior to welding both inside and outside. High quality Slip on Flanges are ideal for lower pressure applications. The Slip On Flange’s ease of fitting and welding also reduces fabrication costs. |

| Flange Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub | Diameter of Raised Face | Length Hub.Y | Bore | Diam. of Bolt Circle | Diam. of Bolt Holes | Number of Bolts | Diam. of Bolts (inch) | KG | LB | |

| inch | dn | O | C | X | G | Y | B | BC | BH | BN | BD | ||

| 1/2″ | 15 | 89.00 | 11.20 | 30.20 | 35.10 | 15.70 | 22.40 | 60.50 | 15.80 | 4 | 1/2″ | 0.4 | 0.9 |

| 3/4″ | 20 | 98.50 | 12.70 | 38.10 | 42.90 | 15.70 | 27.70 | 69.90 | 15.80 | 4 | 1/2″ | 0.7 | 1.5 |

| 1″ | 25 | 108.00 | 14.20 | 49.30 | 50.80 | 17.50 | 34.50 | 79.30 | 15.80 | 4 | 1/2″ | 0.8 | 1.8 |

| 1-1/4″ | 32 | 117.50 | 15.70 | 58.70 | 63.50 | 20.60 | 43.20 | 88.90 | 15.80 | 4 | 1/2″ | 1.2 | 2.6 |

| 1-1/2″ | 40 | 127.00 | 17.50 | 65.00 | 73.20 | 22.40 | 49.50 | 98.60 | 15.80 | 4 | 1/2″ | 1.4 | 3.1 |

| 2″ | 50 | 152.50 | 19.10 | 77.70 | 91.90 | 25.40 | 62.00 | 120.70 | 19.10 | 4 | 5/8″ | 2.2 | 4.8 |

| 2-1/2″ | 65 | 178.00 | 22.40 | 90.40 | 104.60 | 28.40 | 74.70 | 139.70 | 19.10 | 4 | 5/8″ | 3.5 | 7.7 |

| 3″ | 80 | 190.50 | 23.90 | 108.00 | 127.00 | 30.20 | 90.70 | 152.40 | 19.10 | 4 | 5/8″ | 3.8 | 8.4 |

| 3-1/2″ | 90 | 216.00 | 23.90 | 122.20 | 139.70 | 31.80 | 103.40 | 177.80 | 19.10 | 8 | 5/8″ | 5 | 11 |

| 4″ | 100 | 228.50 | 23.90 | 134.90 | 157.20 | 33.30 | 116.10 | 190.50 | 19.10 | 8 | 5/8″ | 5.6 | 12.3 |

| 5″ | 125 | 254.00 | 23.90 | 163.60 | 185.70 | 36.60 | 143.80 | 215.90 | 22.40 | 8 | 3/4″ | 6.5 | 14.3 |

| 6″ | 150 | 279.50 | 25.40 | 192.00 | 215.90 | 39.60 | 170.70 | 241.30 | 22.40 | 8 | 3/4″ | 8.1 | 18 |

| 8″ | 200 | 343.00 | 28.40 | 246.10 | 269.70 | 44.50 | 221.50 | 298.50 | 22.40 | 8 | 3/4″ | 13 | 28.6 |

| 10″ | 250 | 406.50 | 30.20 | 304.80 | 323.90 | 49.30 | 276.40 | 362.00 | 25.40 | 12 | 7/8″ | 18.4 | 40 |

| 12″ | 300 | 482.50 | 31.80 | 365.30 | 381.00 | 55.60 | 327.20 | 431.80 | 25.40 | 12 | 7/8″ | 28.5 | 63 |

| 14″ | 350 | 533.50 | 35.10 | 400.10 | 412.80 | 57.20 | 359.20 | 476.30 | 28.50 | 12 | 1″ | 37.5 | 83 |

| 16″ | 400 | 597.00 | 36.60 | 457.20 | 469.90 | 63.50 | 410.50 | 539.80 | 28.50 | 16 | 1″ | 44.5 | 98 |

| 18″ | 450 | 635.00 | 39.60 | 505.00 | 533.40 | 68.30 | 461.80 | 577.90 | 31.80 | 16 | 1 1/8″ | 54 | 119 |

| 20″ | 500 | 698.50 | 42.90 | 558.80 | 584.20 | 73.20 | 513.10 | 635.00 | 31.80 | 20 | 1 1/8″ | 72 | 158 |

| 24″ | 600 | 813.00 | 47.80 | 663.40 | 692.20 | 82.60 | 616.00 | 749.30 | 35.10 | 20 | 1 1/4″ | 95 | 209 |

0 comments:

Post a Comment