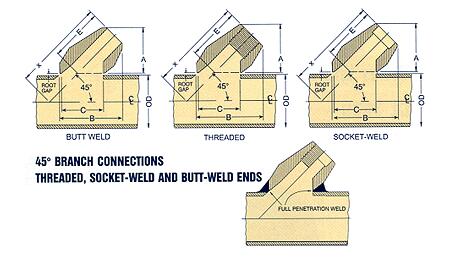

Latrolet, used for 45° lateral connections, is available butt-weld to meet specific reinforcement requirements, and 3000# or 6000# classes for Socket Weld and threaded applications.

Latrolet is used widely abroad in recent years, It is used to connect the reinforced fittings. It can replace the reducing tee, reinforce plate and reinforced pipe. It is used widely more and more in high pressure high temperature large diameter and thick wall pipe. As it is reliability, cheap, simple, good for flow, seriation, standardization and choose easily. It takes place of traditional connecting ways. The body of outlets is made in excellent Forgings. The material is same as pipe’s. We can make outlet from Carbon steel, Alloy steel and Stainless steel. branch or other fittings such as nipple thread plug, Instrument and valve by Butt Welding, Socket Welding and Threaded.

| Nominal Run Pipe Size | Outlet Size | Dimensions | ||||||||||||||||

CL 3000 Threaded and Socket Weld | CL 6000 Threaded and Socket Weld | Standard & XS Butt Weld | Sch. 160 and XXS Butt Weld | |||||||||||||||

| A | B | C | E | A | B | C | E | A | B | C | E | A | B | C | ||||

| 2 1/2 – 1 1/4 | 1/4 | 1 9/16 | 2 11/32 | 1 7/16 | 1 9/16 | 1 9/16 | 2 11/32 | 1 7/16 | 1 9/16 | 1 5/16 | 2 3/32 | 1 7/16 | 1 9/16 | 1 9/16 | 2 5/16 | 1 7/16 | ||

| 12 – 3 | ||||||||||||||||||

| 2 1/2 – 1 1/4 | 3/8 | 1 9/16 | 2 11/32 | 1 7/16 | 1 9/16 | 1 9/16 | 2 11/32 | 1 7/16 | 1 9/16 | 1 5/16 | 2 3/32 | 1 7/16 | 1 9/16 | 1 9/16 | 2 5/16 | 1 7/16 | ||

| 12 – 3 | ||||||||||||||||||

| 2 1/2 – 1 1/4 | 1/2 | 1 9/16 | 2 11/32 | 1 7/16 | 1 9/16 | 1 3/8 | 2 5/32 | 1 7/16 | 1 9/16 | |||||||||

| 12 – 3 | ||||||||||||||||||

| 1 1/2 – 1 1/4 | ||||||||||||||||||

| 5 – 2 | 1/2 | 1 7/8 | 2 3/4 | 1 3/4 | 1 29/32 | 1 13/16 | 2 3/4 | 1 3/4 | ||||||||||

| 12 – 6 | ||||||||||||||||||

| 1 1/2 – 1 1/4 | ||||||||||||||||||

| 5 – 2 | 3/4 | 1 7/8 | 2 3/4 | 1 3/4 | 1 29/32 | 1 11/16 | 2 17/32 | 1 3/4 | 1 29/32 | |||||||||

| 12 – 6 | ||||||||||||||||||

| 2 1/2 – 2 | ||||||||||||||||||

| 5 – 3 | 3/4 | 2 3/16 | 3 1/4 | 2 1/8 | 2 3/16 | 2 1/8 | 3 1/4 | 2 1/8 | ||||||||||

| 12 – 6 | ||||||||||||||||||

| 2 1/2 – 2 | ||||||||||||||||||

| 5 – 3 | 1 | 2 3/16 | 3 1/4 | 2 1/8 | 2 3/16 | 2 1/2 | 3 21/32 | 2 5/8 | 2 15/32 | 1 31/32 | 3 | 2 1/8 | 2 3/16 | 2 1/2 | 3 13/16 | 2 5/8 | ||

| 12 – 6 | ||||||||||||||||||

| 2 1/2 – 2 | ||||||||||||||||||

| 5 – 3 | 1 1/4 | 2 1/2 | 3 27/32 | 2 5/8 | 2 15/16 | 2 3/4 | 4 7/32 | 3 1/32 | 2 5/8 | 2 9/32 | 3 19/32 | 2 5/8 | 2 15/32 | 2 3/4 | 4 1/4 | 3 | ||

| 12 – 6 | ||||||||||||||||||

| 2 1/2 – 2 | ||||||||||||||||||

| 5 – 3 | 1 1/2 | 2 3/4 | 4 7/32 | 3 1/32 | 2 15/32 | 3 31/32 | 3 1/32 | 2 5/8 | ||||||||||

| 12 – 6 | ||||||||||||||||||

| 5 – 4 | ||||||||||||||||||

| 8 – 6 | 1 1/2 | 3 3/8 | 5 7/16 | 4 1/8 | 3 5/32 | 3 3/8 | 5 3/8 | 4 1/8 | ||||||||||

| 12 – 10 | ||||||||||||||||||

| 5 – 4 | ||||||||||||||||||

| 8 – 6 | 2 | 3 3/8 | 5 7/16 | 4 1/8 | 3 5/32 | 3 3/8 | 5 7/16 | 4 1/8 | 3 5/32 | 3 3/16 | 5 1/4 | 4 1/8 | 3 13/32 | |||||

| 12 – 10 | ||||||||||||||||||

| 5 – 4 | ||||||||||||||||||

| 8 – 6 | 2 1/2 | 3 5/32 | 5 3/16 | 4 1/8 | 3 5/32 | |||||||||||||

| 12 – 10 | ||||||||||||||||||

| Order to Specific Run Pipe Sizes | ||||||||||||||||||

| 3 | 3 13/16 | 6 1/4 | 4 31/32 | 3 25/32 | ||||||||||||||

| Order to Specific Run Pipe Sizes | ||||||||||||||||||

| 4 | 4 3/4 | 7 13/16 | 6 7/16 | 4 9/16 | ||||||||||||||

0 comments:

Post a Comment