A barred tee (pigged tee) is a tee or any fitting with a branch used in pipelines that is pigged and has a restriction bar welded internally preventing the pig from traveling down a branch connection. The bars are installed so they are flush with the inside diameter of the pipeline to keep the pig from hanging up when it passes through. The bars should be of a similar or identical material as the parent material.

Bars are placed on the internal side of a tee or really any branch connection big enough to sidetrack a pig while traveling down a pipeline. The size of the bars on the tee should be small enough so that they do not restrict the flow from the branch connection. However, they should be large enough to prevent breakage based on the flow rate through the branch connection of the tee.

Barred tees are pipe fittings with two outlets, one at 90 ° to the connection to the main line that has tiny holes. Barred tees can either be extruded or fabricated and are used to connect two pieces of pipe or fittings. Barred tees are used in pipelines that are pigged.

The specificaition of Barred Tee (Pigged Tee)

Material: Carbon steel, Alloy steel, Stainless steel, etc

Size: Dn100- DN1200

Specification: Sch20- Sch 160 .

Standard: ASME/ANSI B16.9.

Coating: Black painted, varnish oil.

Packing: Wooden case, pallet.

How to design and produce the barred tee (Pigged Tee)?

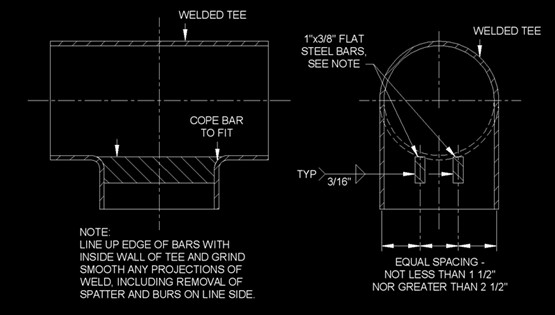

The shape of a Barred tee (Pigged Tee) is like a butt welding pipe tee with some bars in the branch of the tee. The bars are used for preventing the pig from running out in the branch of the main pipe. It is commonly used in a pigged pipeline, so it is also called pigged tee.

The bars in the branch should be installed flush with the inside diameter of main pipe. Commonly the bars are welded with the tees.

It really depends on the kind of pig you are running. A mandral pig will never make the turn into any size branch. A foam pig will pretty much go through whatever pipe has the lower pressure (I once had a 10-inch uncoated foam pig go through a 2-inch weld-o-let on a receiver barrel, but it took a while and did not remain intact). Realistically, I always bar tees since most company standards only allow reducing tees to be used down to 1/2 the run diameter (i.e., I can use a 10X6 tee, but not a 10X4 if I could buy one). 1/2 the diameter can take a coated foam pig and some turbo pigs.

We use foam pigs and nerf ball type pig all the time in my area, we use barred tees down to half the diameter of the main line.

0 comments:

Post a Comment