2205 duplex stainless

steel is mainly composed of 22% Cr, 3% molybdenum and 5-6% Ni nitrogen

composition. It has high strength, better impact toughness and better overall

and local resistance to stress corrosion.

General

properties of stainless steel

Compared with 316L

and 317L austenitic stainless steel, 2205 duplex stainless steel in the

anti-pitting corrosion and corrosion of the better performance, it has a high

corrosion resistance, compared with the austenite, its thermal expansion

coefficient is lower , Higher thermal conductivity.

2205 yield strength

is twice the austenitic stainless steel, this feature allows designers to

reduce the weight of the design of the product, so that this stainless steel

than 316, 317L stainless steel more price advantage.

This stainless steel

is particularly suitable for use in the temperature range of -50 ° F / + 600 ° F. Out of range applications should be used with caution,

especially when applied to welded structures.

The

applications of stainless steel

Pressure vessels,

high pressure storage tanks, high pressure pipes, heat exchangers (chemical

processing industry).

Oil and gas pipeline,

heat exchanger pipe fittings.

Sewage treatment

system.

Pulp and paper

industry classifiers, bleach equipment, storage processing systems.

High-strength

corrosion-resistant environment of the rotary shaft, press roll, blades,

impeller and so on.

Food processing

equipment.

Corrosion

resistance of stainless steel

Uniform

corrosion

Due to the Cr content

(22%), molybdenum (3%) and nitrogen content (0.18%), the corrosion resistance

of 2205 duplex stainless steel is better than 317L and 316L stainless steel in

most environments.

Partial

corrosion resistance

2205 in the Cr,

molybdenum and nitrogen content in the oxidizing and acidic solution, the point

of corrosion and corrosion has a strong resistance.

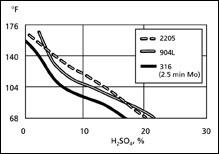

The corrosion curve

in a sulfuric acid solution containing 2000 ppm of chloride was 4 mpy (0.1 mm /

yr)

Anti-stress

corrosion

The dual phase

microstructure of stainless steel improves the corrosion resistance of

stainless steel. At a particular temperature, oxygen, tension and chloride in

the presence of austenitic stainless steel will occur chloride stress

corrosion.

Corrosion

resistance

2205 duplex stainless

steel has a very good anti-corrosion fatigue strength, especially suitable for

processing equipment, effectively avoid susceptible to corrosion environment

and loading cycle.

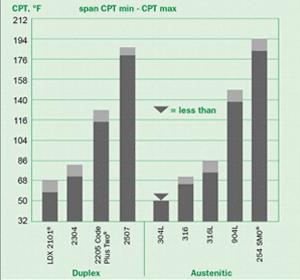

The critical

temperature of the etching in 1M NaCl was measured using an AvestaPolarit etch

cell

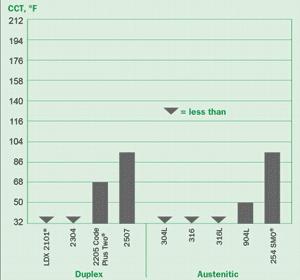

The critical

temperature of corrosion in the gap of 10% FeCl3.6H2O

Uniform

corrosion in wet treated phosphoric acid

Uniform corrosion of

stainless steel

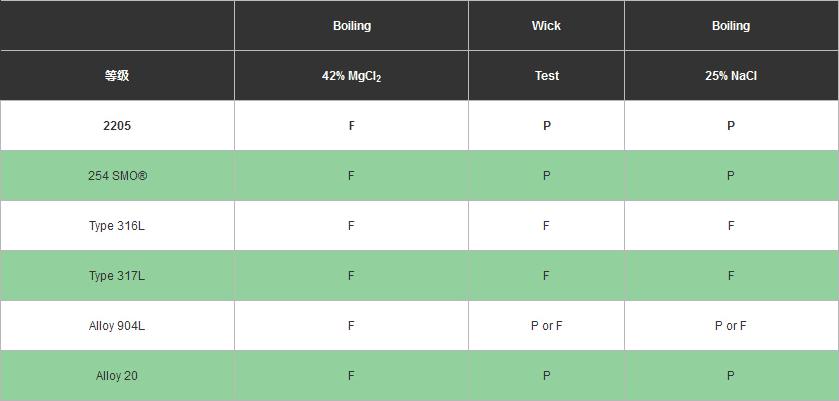

Resistance

to stress cracking

(P = via F = not

passed)

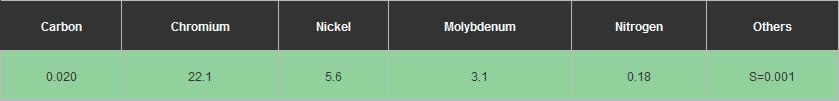

The

chemical composition of stainless steel

Average (% by weight)

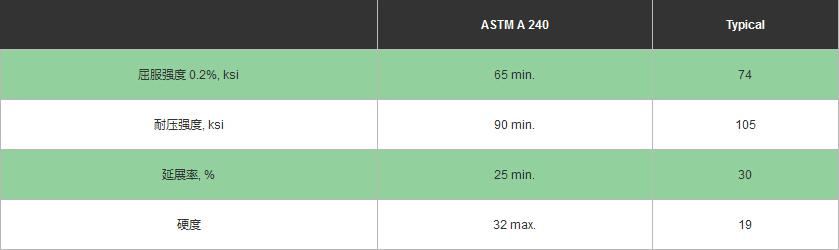

Mechanical

properties of stainless steel

Mechanical properties

at room temperature

Mechanical properties

of stainless steel at room temperature

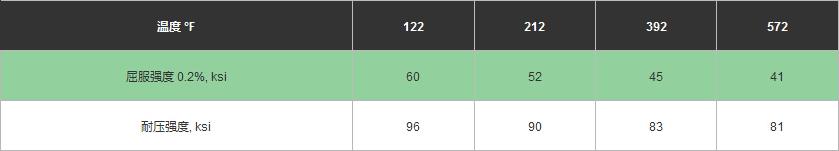

Mechanical

properties at high temperature

Mechanical properties

of stainless steel at high temperature

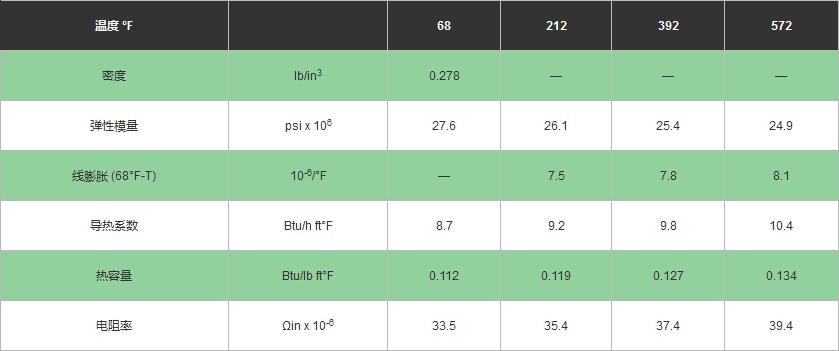

Physical

properties of stainless steel

Physical properties

of stainless steel

structure

The chemical

composition of 2205 achieves the ideal microstructure 50 α / 50 γ after annealing at 1900 ° / 1922 ° F (1040 ° / 1080 ° C).

If the temperature of

the heat treatment is higher than 2000 ° F, the composition of the ferrite

component may be increased.

Like other duplex

stainless steel, 2205 duplex stainless steel is susceptible to intermetallic

precipitation. The intermetallic phase precipitates between 1300 ° F and 1800 ° F, and the precipitation rate is the fastest at 1600 ° F.

The

processing of stainless steel

Thermoforming

We recommend that the

forming should be carried out at temperatures below 600 ° F. During the

thermoforming process, the entire workpiece should be heated as a whole and

should be in the temperature range of 1750 ° F to 2250 ° F. 2205 Duplex stainless steel is very soft at this temperature. If

the temperature is too high, 2205 duplex stainless steel is easy to tear. If

below this temperature, austenite will break. Below 1700 ° F, the intermetallic phase is quickly formed due to temperature and

deformation. After the thermoforming is carried out, it should be immediately

annealed at a minimum temperature of 1900 ° F and

quenched to restore its phase balance, toughness and corrosion resistance. We

do not recommend stress relief, but if this is necessary, the material should

be annealed at a minimum temperature of 1900 ° F and

then rapidly cooled for water quenching.

Cold

forming

2205 duplex stainless

steel can be cut and cold formed. However, due to its own high strength and

hardness of 2205 duplex stainless steel, it is more cold than the austenitic

steel, but also because of its high strength, to fully take into account the

rebound factor.

The

heat treatment of stainless steel

2205 Duplex stainless

steel should be annealed at a minimum temperature of 1900 ° F and then rapidly

cooled for water quenching. This treatment is applied to solid solution

annealing and stress relief. Stress relief is carried out at temperatures below

1900 ° F, which can easily lead to the precipitation of

harmful metal or nonmetallic phases.

Mechanical

machinability

In the high-speed

machine, 2205 duplex stainless steel feed rate and cutting speed and 316L is

the same. If the use of carbonized knife, cutting speed and 316L compared to

about 20% lower, the performance of machinery and equipment and its components

play a key role in this.

Source: wilsonpipeline Pipe Industry Co., Limited (www.wilsonpipeline.com)

0 comments:

Post a Comment