What Is a Loose Flange?

A loose flange (lap joint flange) is a device that is welded onto the end of a piece of pipe to create half of a flanged coupling. Consisting of a flat steel forging with bolt holes around the perimeter and an opening in the center the size of the pipe that is intended to be welded onto the loose flange, the component can be made of carbon steel or stainless steel to meet the intended application. There are loose flange types to fit elbows, valves and nearly every type of pipeline component in use.

Due to the nature of pipelines, the connections and couplings can rarely be constructed in advance. The use of a loose flange allows a worker to create a coupling in any location along the pipeline that is feasible. The worker simply cuts the pipe at the required location and places a loose flange onto the end of the pipe. After carefully preparing the pipe to weld, the loose flange is welded permanently to the end of the pipe. If a valve or elbow is required, the worker simply welds the flange onto the elbow or valve as well as the pipe, and the union is made.

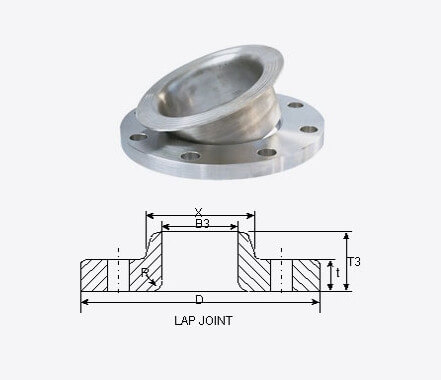

Lap Joint Flanges have all the same common dimensions as any other flange named on this page however it does not have a raised face, they used in conjunction with a “Lap Joint Stub End”.

These flanges are nearly identical to a Slip On flange with the exception of a radius at the intersection of the flange face and the bore to accommodate the flanged portion of the Stub End.

Their pressure-holding ability is little, if any, better than that of Slip On flanges and the fatigue life for the assembly is only one tenth that of Welding Neck flanges.

They may be used at all pressures and are available in a full size range. These flanges slip over the pipe, and are not welded or otherwise fastened to it. Bolting pressure is transmitted to the gasket by the pressure of the flange against the back of the pipe lap (Stub End).

Lap Joint flanges have certain special advantages:

Freedom to swivel around the pipe facilitates the lining up of opposing flange bolt holes.

Lack of contact with the fluid in the pipe often permits the use of inexpensive carbon steel flanges with corrosion resistant pipe.

In systems which erode or corrode quickly, the flanges may be salvaged for re-use.

what is the advantage of the lap joint flange?

1. Because of the structure of a Lap joing flange , it can swivel around the stub end and pipe lining. When the piping system is assembe and disassemble frequently, it is better to use a Lap joint flange. It means the flange can work even the two flanges bolt holes are misalignment .

2. In a corrosive situation, the flange joints need to be exchange very soon. To a lap joint flange, only the stub end is touch with the pipe and fluid , the backing flange no need to touch it . It means you could only replace the stub end , no need to replace the backing flange , so the lap joint flange can decrease the cost of the piping systems.

3.The backing flange and the stub end is seperated , so we can use two different materials for the two pieces. it can work for more complicated application.

Source: wilsonpipeline Pipe Industry Co., Limited (www.wilsonpipeline.com)

0 comments:

Post a Comment