Since its inception in the early 20th century, with the continuous development of its research and development and production technology, the standard of stainless steel has been gradually established in various industrialized countries, and the establishment and perfection of stainless steel standard has promoted the progress of stainless steel production technology.

Raw Materials

Stainless steels are made of some of the basic elements found in the earth: iron ore, chromium, silicon, nickel, carbon, nitrogen, and manganese. Properties of the final alloy are tailored by varying the amounts of these elements. Nitrogen, for instance, improves tensile properties like ductility. It also improves corrosion resistance, which makes it valuable for use in duplex stainless steels.

The Manufacturing

Process

The manufacture of stainless steel involves a series of processes. First, the steel is melted, and then it is cast into solid form. After various forming steps, the steel is heat treated and then cleaned and polished to give it the desired finish. Next, it is packaged and sent to manufacturers, who weld and join the steel to produce the desired shapes.

Melting and casting

1 The raw materials are first melted together in an electric furnace. This step usually requires 8 to 12 hours of intense heat. When the melting is finished, the molten steel is cast into semi-finished forms. These include blooms (rectangular shapes), billets (round or square shapes 1.5 inches or 3.8 centimeters in thickness), slabs, rods, and tube rounds.

Forming

2 Next, the semi-finished steel goes through forming operations, beginning with hot rolling, in which the steel is heated and passed through huge rolls. Blooms and billets are formed into bar and wire, while slabs are formed into plate, strip, and sheet. Bars are available in all grades and come in rounds, squares, octagons, or hexagons 0.25 inch (.63 centimeter) in size. Wire is usually available up to 0.5 inch (1.27 centimeters) in diameter or size. Plate is more than 0.1875 inch (.47 centimeter) thick and over 10 inches (25.4 centimeters) wide. Strip is less than 0.185 inch (.47 centimeter) thick and less than 24 inches (61 centimeters) wide. Sheet is less than 0.1875 (.47 centimeter) thick and more than 24 (61 centimeters) wide.

Heat treatment

3 After the stainless steel is formed, most types must go through an annealing step. Annealing is a heat treatment in which the steel is heated and cooled under controlled conditions to relieve internal stresses and soften the metal. Some steels are heat treated for higher strength. However, such a heat treatment—also known as age hardening —requires careful control, for even small changes from the recommended temperature, time, or cooling rate can seriously affect the properties. Lower aging temperatures produce high strength with low fracture toughness, while higher-temperature aging produces a lower strength, tougher material.

Though the heating rate to reach the aging temperature (900 to 1000 degrees Fahrenheit or 482 to 537 degrees Celsius) does not effect the properties, the cooling rate does. A post-aging quenching (rapid cooling) treatment can increase the toughness without a significant loss in strength. One such process involves water quenching the material in a 35-degree Fahrenheit (1.6-degree Celsius) ice-water bath for a minimum of two hours.

The type of heat treatment depends on the type of steel; in other words, whether it is austenitic, ferritic, or martensitic. Austenitic steels are heated to above 1900 degrees Fahrenheit (1037 degrees Celsius) for a time depending on the thickness. Water quenching is used for thick sections, whereas air cooling or air blasting is used for thin sections. If cooled too slowly, carbide precipitation can occur. This buildup can be eliminated by thermal stabilization. In this method, the steel is held for several hours at 1500 to 1600 degrees Fahrenheit (815 to 871 degrees Celsius). Cleaning part surfaces of contaminants before heat treatment is sometimes also necessary to achieve proper heat treatment.

Descaling

4 Annealing causes a scale or build-up to form on the steel. The scale can be removed using several processes. One of the most common methods, pickling, uses a nitric-hydrofluoric acid bath to descale the steel. In another method, electrocleaning, an electric current is applied to the surface using a cathode and phosphoric acid, and the scale is removed. The annealing and descaling steps occur at different stages depending on the type of steel being worked. Bar and wire, for instance, go through further forming steps (more hot rolling, forging, or extruding) after the initial hot rolling before being annealed and descaled. Sheet and strip, on the other hand, go through an initial annealing and descaling step immediately after hot rolling. After cold rolling (passing through rolls at a relatively low temperature), which produces a further reduction in thickness, sheet and strip are annealed and descaled again. A final cold rolling step then prepares the steel for final processing.

Cutting

5 Cutting operations are usually necessary to obtain the desired blank shape or size to trim the part to final size. Mechanical cutting is accomplished by a variety of methods, including straight shearing using guillotine knives, circle shearing using circular knives horizontally and vertically positioned, sawing using high speed steel blades, blanking, and nibbling. Blanking uses metal punches and dies to punch out the shape by shearing. Nibbling is a process of cutting by blanking out a series of overlapping holes and is ideally suited for irregular shapes.

Stainless steel can also be cut using flame cutting, which involves a flame-fired torch using oxygen and propane in conjunction with iron powder. This method is clean and fast. Another cutting method is known as plasma jet cutting, in which an ionized gas column in conjunction with an electric arc through a small orifice makes the cut. The gas produces extremely high temperatures to melt the metal.

Finishing

6 Surface finish is an important specification for stainless steel products and is critical in applications where appearance is also important. Certain surface finishes also make stainless steel easier to clean, which is obviously important for sanitary applications. A smooth surface as obtained by polishing also provides better corrosion resistance. On the other hand, rough finishes are often required for lubrication applications, as well as to facilitate further manufacturing steps.

Surface finishes are the result of processes used in fabricating the various forms or are the result of further processing. There are a variety of methods used for finishing. A dull finish is produced by hot rolling, annealing, and descaling. A bright finish is obtained by first hot rolling and then cold rolling on polished rolls. A highly reflective finish is produced by cold rolling in combination with annealing in a controlled atmosphere furnace, by grinding with abrasives, or by buffing a finely ground surface. A mirror finish is produced by polishing with progressively finer abrasives, followed by extensive buffing. For grinding or polishing, grinding wheels or abrasive belts are normally used. Buffing uses cloth wheels in combination with cutting compounds containing very fine abrasive particles in bar or stick forms. Other finishing methods include tumbling, which forces movement of a tumbling material against surfaces of parts, dry etching (sandblasting), wet etching using acid solutions, and surface dulling. The latter uses sandblasting, wire brushing, or pickling techniques.

The Smelting process of stainless steel production

First to introduce the basic principles of stainless steel smelting.

Stainless steel contains at least 10.5% Cr, which is different from carbon steel production. Therefore, in the decarburization reaction, reaction occurs:

Cr3O4 + 4 [C] = 3 [Cr] + 4CO

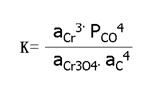

Reaction equilibrium constant

Cr in the high chromium steel, Cr than C priority oxidation, in the normal smelting temperature, C below 0.03%, the balance of Cr is only about 4%; improve the temperature can improve the balance of Cr content, but refractory unbearable. Such as: 18% Cr of molten steel, the temperature to reach more than 1900 ℃, for the development of a partial pressure of CO to reduce the smelting method. Stainless steel commonly used refining methods:

AOD, VOD, K-OBM-S, K-BOP and so on), RH-BMP method and so on, which can be used in the process of arc furnace, direct arc melting, AOD, VOD, OB method, in which the AOD method, VOD method dominant. Through the use of two-step and three-step process to produce smelting stainless steel, can produce large-scale low-carbon, ultra-low carbon stainless steel, but also can improve the recovery of Cr.

1) Several smelting methods of stainless steel:

One step:

EAF Original Electric Furnace Direct Production Process

Two-step method:

EAF + AOD EAF + VOD

EAF + CLU LD-OB + VOD

Three steps:

EAF + K-OBM-S + VOD or AOD + (LF)

EAF + AOD + VOD

EAF + LD-OB + VOD

2) The advantages and disadvantages of AOD and VOD:

AOD smelting has the advantages of low investment cost, high decarburization speed and high production efficiency, high thermal efficiency and low cost of smelting. It has good stirring effect and is easy to de-S and O. The equipment is relatively simple and the process is easy to grasp. AOD around the use of stainless steel production, the disadvantage is the production of low C, N steel difficult.

VOD smelting off C, Cr-effective, good deoxidation effect; suitable for the production of low C, N steel and so on. Shortcomings High investment costs, equipment maintenance difficulties.

The process hot rolling of stainless steel

The strip accounts for about 70% of the total output of stainless steel. Stainless steel hot strip mainly by the hot rolling mill, steckel mill and other production, including hot rolling mill, which is characterized by large output, low cost, good quality, is widely used in many steel mills. However, the number of stainless steels produced by the improved Steckel Mill in the world is increasing, such as AVESTA and YUSCO. Heavy plate generally by the four-roll reversing mill-based production.

The cold rolling process of Stainless steel

Stainless steel is a high alloy steel, rolling deformation resistance, in order to carry out high-efficiency, high-precision rolling, rigidity should be used in large rolling mill, generally multi-roll cold rolling mill.

The heat treatment process of stainless steel

Stainless steel heat treatment through the use of the best performance, or create conditions for subsequent processing, the general stainless steel in the factory before the need for heat treatment.

Martensitic stainless steel: softening (martensite → ferrite + carbide); carbide diffusion;

degree.

Ferritic stainless steel: to improve plasticity; adjust the grain size.

Austenitic stainless steel: Carbide solid solution; Adjust grain size; Soften; Reduce δ ferrite.

Duplex stainless steel: carbide solid solution; improve plasticity; reduce the brittle phase precipitation.

The common standard of stainless steel

Since its inception in the early 20th century, with the continuous development of its research and development and production technology, its standards are gradually established in the industrialized countries, the establishment and perfection of stainless steel standards, in turn, to promote the progress of stainless steel production technology, Promote the improvement of product quality, the development of stainless steel products in the market trade, play a very important role.

China National (GB / T) standards:

Hot – rolled stainless steel sheets and strip GB / T

Cold – rolled stainless steel sheets and strips GB / T

Heat – resisting steel plates and strips GB / T

GB / T1220 stainless steel rods

GB / T8165 stainless steel composite plate and strip

Stainless steel and heat – resistant steel, designation and chemical composition GB / T

Other special stainless steel standards, as well as the enterprise standards

Commonly used foreign standard (international common standard):

ASTM A240 (M) stainless steel plate (American Standard)

ASME A 240 (M) Stainless Steel Plate (American Standard)

ASTM A 480 (M) Stainless Steel Plate (American Standard)

JIS4305 stainless steel cold rolled steel sheet (Japanese standard)

JIS4304 stainless steel hot-rolled steel sheet (Japanese standard)

EN10028 Stainless steel for pressure vessels (EU)

EN10088 General purpose sheets, plates and strips with stainless steel (EU)

Other European EN series standards

0 comments:

Post a Comment