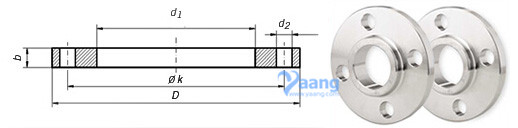

DIN 2502 PN16 Plate Flange (Slip On Flange)

DIN Plate Flange (Slip On Flange):

| Flange Dimensions |

| Germany standard flange DIN 2502 for soldering or welding Nominal Pressure 16 | ||||||||

| Flansche, glatt zum löten oder schweißen DIN 2502 Nenndruck 16 | ||||||||

| Brides plates a souder DIN 2502 pression nominale 16 | ||||||||

| DIN 2502 PN 16 PLATE FLANGE DIMENSIONS (in mm) | ||||||||

Nominal Pipe Size | Diameter of | Flange Dia | Flange I.D | Thk of Flanges | Dia of Bolt Cirlce | No. of | Dia of Bolt Holes | Weight |

DN | Pipe | D | D5 | B | K | holes | D2 | KG |

| 10 | 17.20 | 90 | 17.70 | 14 | 60 | 4 | 14 | 0.60 |

| 15 | 21.30 | 95 | 22.00 | 14 | 65 | 4 | 14 | 0.67 |

| 20 | 26.90 | 105 | 27.60 | 16 | 75 | 4 | 14 | 0.94 |

| 25 | 33.70 | 115 | 34.40 | 16 | 85 | 4 | 14 | 1.11 |

| 32 | 42.40 | 140 | 43.10 | 16 | 100 | 4 | 18 | 1.62 |

| 40 | 48.30 | 150 | 49.00 | 16 | 110 | 4 | 18 | 1.85 |

| 50 | 60.30 | 165 | 61.10 | 18 | 125 | 4 | 18 | 2.46 |

| 65 | 76.10 | 185 | 77.10 | 18 | 145 | 4 | 18 | 2.99 |

| 80 | 88.90 | 200 | 90.30 | 20 | 160 | 8 | 18 | 3.61 |

| 100 | 114.30 | 220 | 115.90 | 20 | 180 | 8 | 18 | 3.99 |

| 125 | 139.70 | 250 | 141.60 | 22 | 210 | 8 | 18 | 5.41 |

| 150 | 168.30 | 285 | 170.50 | 22 | 240 | 8 | 22 | 6.55 |

| 175 | 193.70 | 315 | 196.10 | 24 | 270 | 8 | 22 | 8.42 |

| 200 | 219.10 | 340 | 221.80 | 24 | 295 | 12 | 22 | 8.97 |

| 250 | 273.00 | 405 | 276.20 | 26 | 355 | 12 | 26 | 12.76 |

| 300 | 323.90 | 460 | 327.60 | 28 | 410 | 12 | 26 | 16.60 |

| 350 | 355.60 | 520 | 359.70 | 30 | 470 | 16 | 26 | 24.08 |

| 400 | 406.40 | 580 | 411.00 | 32 | 525 | 16 | 30 | 30.20 |

| 450 | 457.00 | 640 | 462.30 | 38 | 585 | 20 | 30 | 41.67 |

| 500 | 508.00 | 715 | 513.60 | 38 | 650 | 20 | 33 | 52.87 |

| 600 | 610.00 | 840 | 616.50 | 42 | 770 | 20 | 36 | 77.58 |

| 700 | 711.00 | 910 | 716.00 | 44 | 840 | 24 | 36 | 77.13 |

| 800 | 813.00 | 1025 | 818.00 | 50 | 950 | 24 | 39 | 106.35 |

| 900 | 914.00 | 1125 | 920.00 | 54 | 1050 | 28 | 39 | 125.39 |

| 1000 | 1016.00 | 1255 | 1022.00 | 60 | 1170 | 28 | 42 | 177.99 |

NOTE: |

If any inquiry about products, please feel free to contact us sales@wilsonpipeline.com

0 comments:

Post a Comment