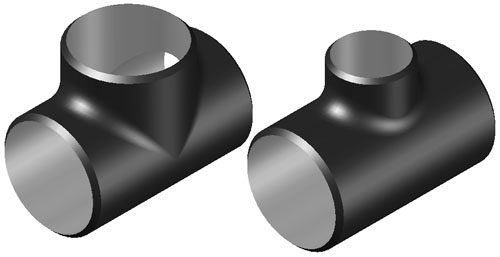

BUT TWELD FITTINGS: STRAIGHT TEE AND REDUCING TEE

The primary purpose of a Tee is to make a 90° branch from the main run of pipe. Standard there are 2 possibilities, on behalf of the equal tee and reducing tee. The equal tee (or straight tee) is used as the branch has the same diameter as the run-pipe. The reducing tee is used as the branch has a smaller diameter as the run-pipe.

• DIMENSIONS AND STANDARDS

When we talk about a tee NPS 3, a equal tee or straight tee is intended.

With a tee NPS 3 x 2 a reducing tee is intended. Although, officially a reducing tee will be indicated by 3 diameters, namely 3 x 3 x 2 (A x B x C).The A & B measure stands for the Nominal Pipe Size of Run-Pipe, C measure stands for Nominal Pipe Size of Outlet.

This designation actually is superfluous, but comes from the time that tees were available in 3 different ends of diameters, such as 4 x 3 x 2 (A x B x C). In this implementation of course it is necessary, to specify 3 different sizes.

That kind of tees is probably no longer available. Applying a equal tee with a concentric reducer or eccentric reducer is now the usual practice.

A straight buttwelding Tee or equal buttwelding Tee is available for all common diameters. A Reducing Tee not, because many diameters are not produced, or can not be produced. As an example: A Reducing Tee NPS 6 x 4 is a standard item for most suppliers, but A Reducing Tee NPS 16 x 2 is probably not available by any supplier. It would also not economical to use a NPS 16 tee with a NPS 2 outlet; in such situations a Branch Fitting will be used or a Branch Connection will be made.

In addition to the defined tees, there are straight cross and reducing cross.

Straight crosses are generally stock items, reducing crosses are often difficult to obtain.

• WALL THICKNESS TEE

By the shape of a tee, the wall thickness can be a critical item. ASME B16.9 only standardizes the end-to-end dimensions, center-to-end dimensions and some “squareness” dimensional tolerances. The wall thickness at the weld line location even is standardized, but not through the rest of the fitting. The standard states that the minimum tolerance will be within 12.5% of the minimum ordered wall thickness of the pipe. A maximum tolerance is specified only at the ends of the fitting.

Many providers of welding tees (and elbows) provide one schedule greater thickness so that sufficient wall thickness, after forming, remains. In Tee′s, the crotch radius (T) varies from one manufacturer to another, but some establish itself as a requirement, 1.3 times the wall thickness to maintain the crotch.

ASME B16.9-2003 Section 2.2 Design of fittings says:

…it is expected that some portion of formed fittings may have to be thicker than the pipe wall with which the fitting is intended to be used

Because there is no maximum tolerance for some parts of the fitting, the customer itself must indicate his requirements. Depending on a customer specification, the manufacturer must certify that the manufactured tee, is made according to the requested requirements. He can do that with additional drawings, with additional wall thickness measurements et cetera verified by an independent party or a customers inspector.

All these additional tests cost money, so it can happen, that the additional costs, many times higher, as the tee itself.

0 comments:

Post a Comment